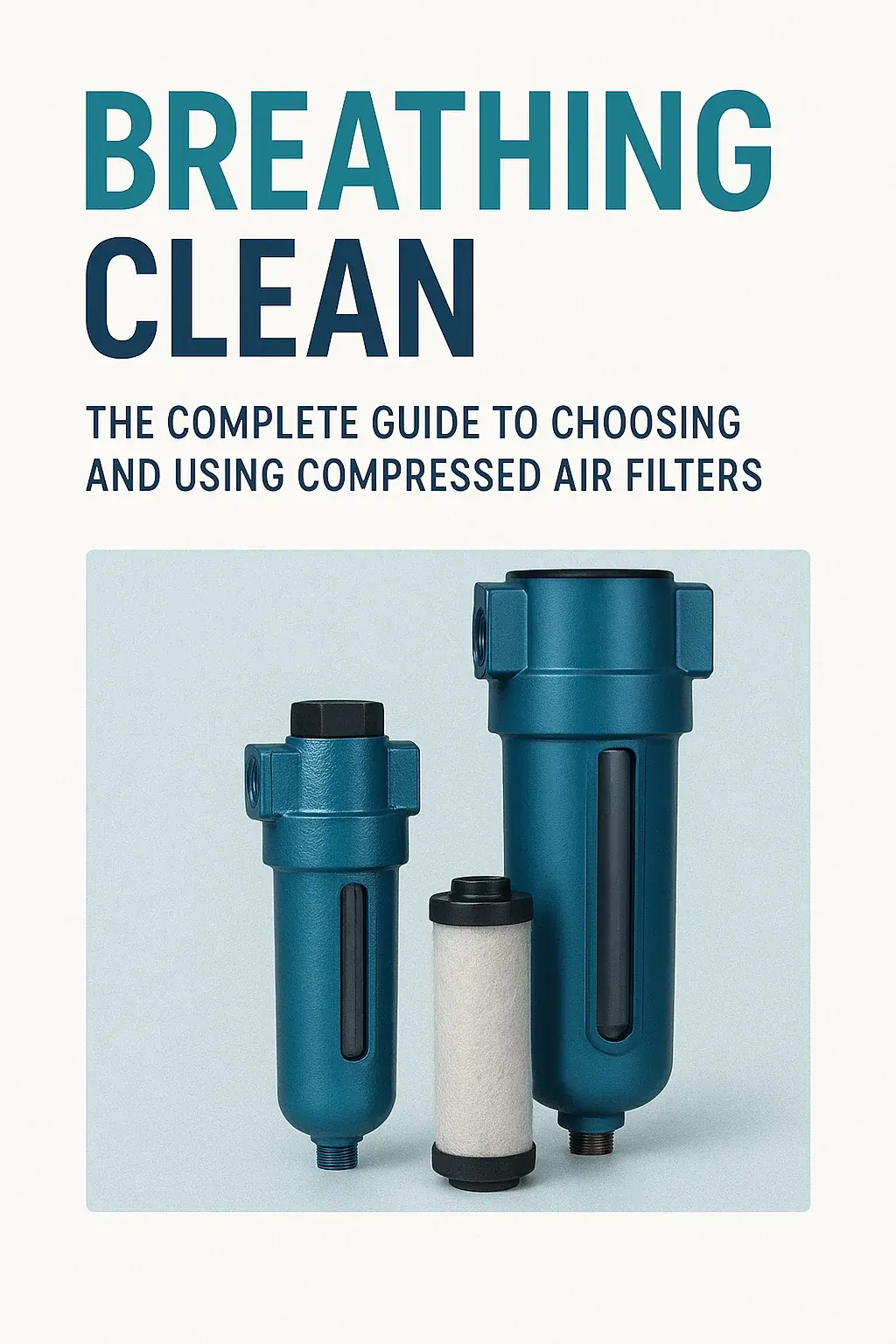

When it comes to industrial operations, precision manufacturing, or even running pneumatic tools in your workshop, compressed air is often the unsung hero. But here’s the catch — compressed air straight from the compressor isn’t as “clean” as it looks. Dust, oil vapor, moisture, and microscopic particles can hitch a ride, damaging equipment and compromising final products.

Enter the compressed air filter — the protective gatekeeper that ensures your air supply is clean, dry, and safe for both machinery and human use.

In this comprehensive guide, we’ll explore why compressed air filtration matters, how it works, the types available, and how to choose the right one for your application. Whether you’re a factory owner, an engineer, or a hobbyist, understanding this small but mighty device can save you serious money, downtime, and headaches.

1. Why Compressed Air Needs Filtration

Compressed air might seem clean, but in reality, the process of compression concentrates impurities. The air you breathe contains dust, pollen, moisture, and sometimes trace oil particles. When compressed, these contaminants become more concentrated and potentially harmful.

Some common threats in unfiltered compressed air include:

-

Dust and solid particles – From environmental dust to rust from piping.

-

Oil aerosols – From lubricated compressors.

-

Moisture – Humidity in the air turns into water droplets during compression.

-

Microorganisms – Bacteria and spores can survive in moist environments inside air systems.

Without proper filtration, these impurities can:

-

Clog pneumatic tools.

-

Corrode pipelines.

-

Contaminate products (especially in food, pharma, or electronics).

-

Cause costly downtime due to equipment failure.

2. How a Compressed Air Filter Works

The principle is straightforward: a compressed air filter removes contaminants before the air reaches your application point.

Basic stages of filtration include:

-

Pre-filtration – Removes larger particles like dust or rust flakes.

-

Coalescing filtration – Removes oil mist and fine droplets by forcing them to merge and drop out of the air stream.

-

Adsorption – Activated carbon filters capture vapor-phase contaminants, odors, and some chemicals.

Air passes through filter elements made of specialized media (fiberglass, sintered bronze, or activated carbon), which trap particles and moisture while letting clean air pass through.

3. Types of Compressed Air Filters

Not all filters are built the same. The type you need depends on your application, required air quality, and budget.

a) Particulate Filters

-

Purpose: Remove solid contaminants like dust, dirt, and rust.

-

Common Uses: General manufacturing, automotive workshops.

-

Filtration Level: Down to 1 micron or finer.

b) Coalescing Filters

-

Purpose: Capture oil and water aerosols.

-

Common Uses: Protecting sensitive equipment like air bearings or spray painting systems.

-

Filtration Level: Down to 0.01 micron for oil and moisture removal.

c) Activated Carbon Filters

-

Purpose: Remove oil vapors, odors, and certain chemicals.

-

Common Uses: Food and beverage, pharmaceutical production, electronics manufacturing.

-

Filtration Level: Not rated in microns — measured by odor/vapor reduction efficiency.

d) Sterile Filters

-

Purpose: Eliminate microorganisms from compressed air.

-

Common Uses: Medical, biotech, and food industries.

-

Filtration Level: Down to 0.01 micron for bacteria removal.

4. Where Compressed Air Filters Are Used

Compressed air filters aren’t only for massive industrial setups. Their applications span across industries and even personal projects:

-

Food & Beverage Production – Ensures hygienic air for packaging and processing.

-

Pharmaceutical Manufacturing – Prevents contamination in drug production.

-

Automotive Industry – Keeps painting and pneumatic tools free from oil spots or dust.

-

Electronics Manufacturing – Protects sensitive circuits from static and dust.

-

General Workshops – Extends tool life and ensures quality work.

5. Benefits of Using a Compressed Air Filter

a) Improved Equipment Longevity

Filtered air means less wear and tear on pneumatic tools, valves, and actuators.

b) Reduced Maintenance Costs

Preventing contamination means fewer repairs and replacements.

c) Higher Product Quality

Especially important in industries where a single speck of dust can ruin a batch.

d) Compliance with Standards

Certain industries must meet ISO 8573-1 air quality standards, which require filtration.

e) Safer Working Environment

Removes harmful contaminants that can affect worker health.

6. How to Select the Right Compressed Air Filter

Choosing the correct filter involves more than just picking one off the shelf. Consider:

-

Air Quality Requirements – What level of filtration do you need? Check ISO standards for your industry.

-

Flow Rate – The filter must handle the air volume without causing excessive pressure drop.

-

Operating Pressure – Ensure the filter can handle your compressor’s max pressure.

-

Type of Contaminants – Different filters target solids, liquids, or vapors.

-

Maintenance Accessibility – Easy filter element replacement saves downtime.

7. Maintenance Tips for Compressed Air Filters

Even the best filter will fail if neglected. To keep yours in top condition:

-

Check filter elements regularly – Replace when clogged or as per manufacturer schedule.

-

Drain moisture – Many filters have automatic or manual drains.

-

Monitor pressure drop – A rising differential pressure means the filter is clogging.

-

Use the right replacement parts – Incorrect elements can reduce efficiency.

8. The Role of Filtration in Energy Efficiency

Many overlook that clogged filters cause pressure drop, forcing compressors to work harder and use more energy. By keeping filters clean and correctly sized, you reduce operational costs and lower your carbon footprint.

A 1 psi pressure drop can increase energy consumption by about 0.5% — so a neglected filter could be quietly adding thousands to your yearly electricity bill.

9. Common Myths About Compressed Air Filters

Myth 1: All filters are the same.

Reality: Filtration ratings, materials, and purposes vary greatly. Using the wrong one wastes money and risks contamination.

Myth 2: You can “clean” and reuse all filter elements.

Reality: Some can be cleaned, but many are designed for one-time use to ensure efficiency.

Myth 3: Filters are optional in small workshops.

Reality: Even hobby airbrush artists notice a quality difference when using filtered air.

10. Future Trends in Compressed Air Filtration

Technology is evolving to make filtration smarter and more sustainable:

-

Self-monitoring filters – Sensors alert you when maintenance is needed.

-

Eco-friendly filter media – Biodegradable materials reduce environmental impact.

-

Integrated air treatment units – Combine drying, filtering, and monitoring in one compact system.

As industries demand cleaner air and stricter compliance, these innovations will become standard.

Final Thoughts

A compressed air filter might be small compared to your overall system, but its role is enormous. From extending equipment life to ensuring product quality, it’s an investment that pays for itself many times over.

Whether you’re running a massive manufacturing plant or a modest workshop, clean air isn’t optional — it’s essential. By understanding how filters work, the types available, and proper maintenance, you can keep your operations running smoothly and efficiently for years to come.

Clean air isn’t just about breathing easier — in the world of compressed air systems, it’s about working smarter, lasting longer, and performing better.